SOLUTIONS FOR THE

EXTRUSION AND PLASTIC FILM CALENDERING SECTOR

The blown film or tubular film extrusion process is the most common method for the manufacturing of plastic films, and in general it is used for processing of plastic thermoplastic bags.

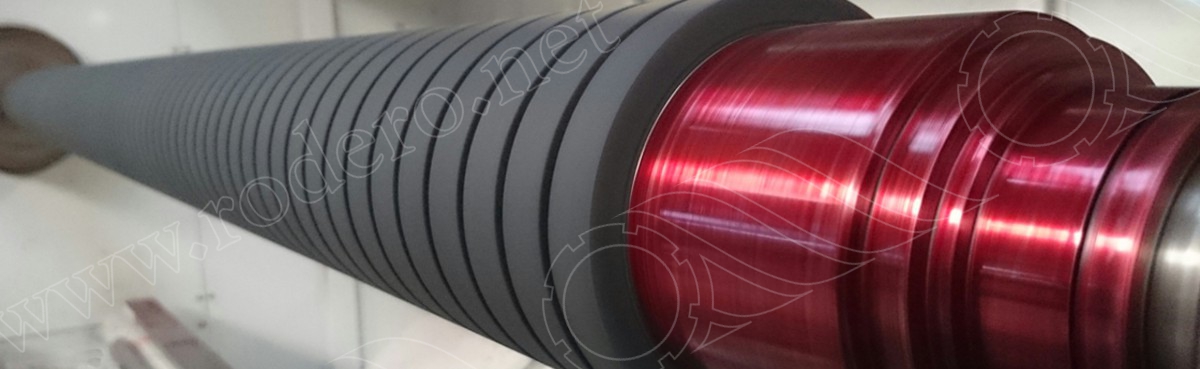

From the calendering until the last rewinding from the plastic roll, there are used a big quantity of rollers both metallic rollers and rubber coated rollers. Given that the plastic film thickness is obtained in the calendering process, it is of vital importance the perfect finish of the finish roller. It is also very important the following winding process, where different guide rollers and tensor rollers that avoid folds are involved.

Between transport rollers and winding rollers usually we find the treatment systems and static charges removing systems composed by electrically conductive brushes with earth connection that rub the plastic film surface already collapsed, in order to eliminate static electricity, that it is why it is of particular importance a good electricity conductivity of the coated rubber.

- Rubber roller clamps

- Corona treatment rollers

- Guide and tensor rollers

- Pressure, motorized, and rewinding rollers for film calendering

- Chromed metallic, rectified and mirror-polished or frosted-polished rollers

- Rubber or silicone technical parts for sealing rings, tubes, suction cups, holders, etc.. for different industrial machines.

At Rodero we are experts in rollers used in plastic film extrusion. The main characteristics of our coatings are:

- Excellent abrasion resistance

- Excellent behaviour to high temperatures

- High elasticity and recovery capacity

- Very good resistance to ozone and sun light