We design and compose rubber formulations with excellent quality, exclusively reserved for our products and suitable for all type of industrial applications

- Excellent elasticity and recovery against deformation.

- Resistance to abrasion and tearing.

- Chemical resistance against oils, alkalines, acids, solvents, etc.

- Resistance against ozone and sunlight.

- Excellent behaviour against high temperatures.

- Electricity resistance or coductivity depending on the requirements.

Extended properties table

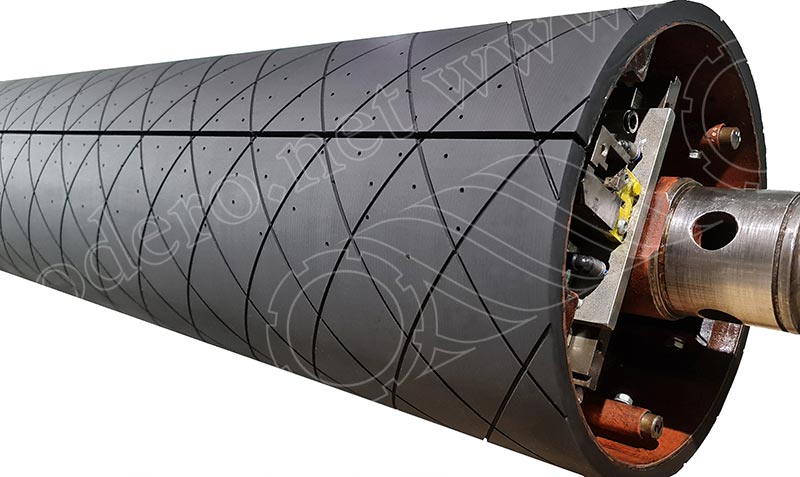

RUBBER ROLLER COATING

Thanks to the confidence that important machinery manufactures have placed on us, our rollers rotate in the entire world.

Our main activity is the coating of industrial rollers with all kind of rubbers, such as NR, NBR, SBR, BR, IIR, CR, CSM, EPDM, silicone, ebonite, etc. covering all the requirements demanded by the market.

The knowledge accumulated in our career of more than 60 years, combined with the constant investment in new technologies, allows us to perform any kind of covering and guarantee its perfect functioning, from the most basic until those with maximum requirements on their performances.

The coatings of the ROCAUCHO line offer numerous advantages:

We choose the ideal rubber for each covering from our database with over 200 formulations.

Surface treatment of the metal core and use of adhesives of leading brands that guarantee a perfect rubber-metal bond.

For regained rollers, we guarantee the complete removal of the old coating and replacement by the new one. The generated residues are managed by autorized agents, always respecting the environment.

Perfect finish guarantee, with final verifications according to our protocols of our ISO 9001 quality system.

Delivery times adapted to our customers requirements, respecting the productive process that guarantees the quality of the coating.

In addition to roller coating we offer the following services:

- Dynamic balancing.

- Rectifieds with fine or superfine finishes with different roughness values.

- Parabolic curved, conical or double conical.

- We manufacture complete rollers (metal core + rubber).

- Verification and axes repair, plummer housing, seals, etc..

- Spiral, radial, axial, diamond grooves, etc..

We produce coatings with a range of hardness from 20 Sh.A until 100 Sh.A.

The bilayer coatings combine high elasticity with an effective resistance to surface abrassion.

Equip a perfect finish is vital for a proper functioning of the roller.

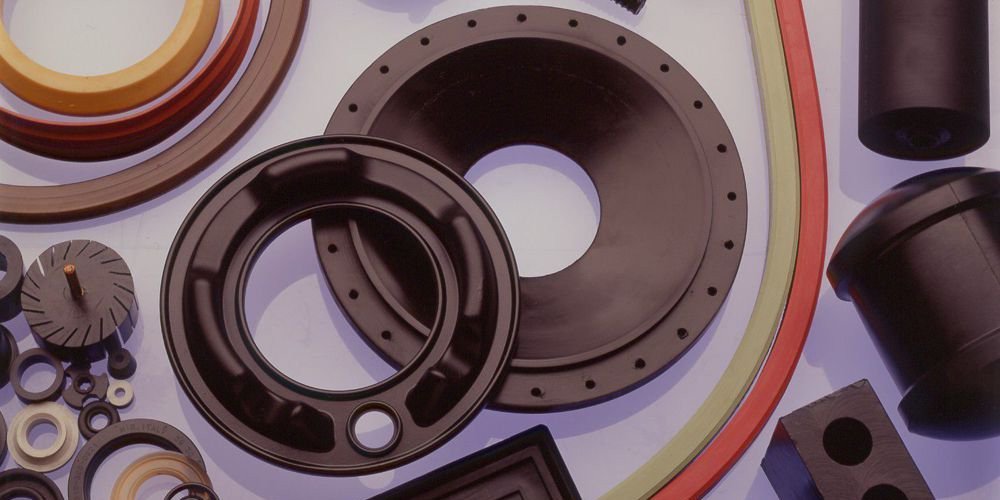

TECHNICAL RUBBER PARTS

The difficulty of a part is not an issue, it is a challenge for us.

We manufacture all kind of technical rubber parts or metal-rubber, with different technologies with systems as compression, transfer, injection or embossing.

Our technical office together with our customers constantly develops projects for obtaining pieces that must support mechanical conditions, temperatures, chemichal and environmental attacks.

We controle the entire process,consequently we design the part, the mould manufacturing, its pressing/injection and the following quality control.

Our technical parts offer comprises:

- Pulleys

- Wheels

- Seals

- Membranes

- Profiles

- Suction cups

- Gussets

- Silent block bushes

- Bushings

- Etc...

OTHER RUBBER PRODUCTS

Our rubber products offer is completed with:

- Non abrasive coverings of deposits, barrels, etc..

- Rubber sheets of different qualities, densisties and hardness.

- Handling, cutting and embossing rubber sheets.

- Cold bond of rubber-rubber or rubber-metal.

- Customized membranes for vacuum presses.

- Extruded profiles of different geometries.